The vacuum pump market in the UK is being driven by increasing investments in end-user industries. The boom in shale gas production is pushing the demand for new types of pumps for the chemical and oil and gas industries. These industries are experiencing a low level of productivity and must replace old equipment with the latest technologies.

What Is a Vacuum Pump?

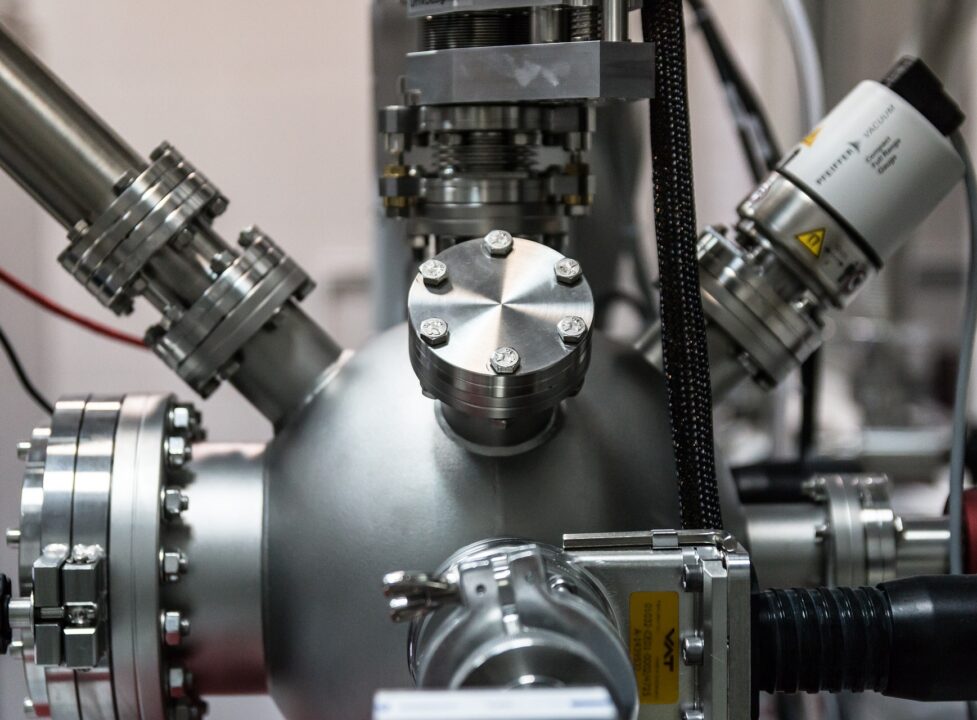

A vacuum pump is a key piece of equipment for many industries. This type of pump is vital to electron microscopes, photolithography, freeze-drying, and storage of reactive research substances. In the space industry, vacuum pumps are being developed for high-speed communications and data transmission. They are also used in satellites to make them lighter and more efficient. These are some of the ways that vacuum pumps help us live better. And what’s more, they are indispensable in the development of new technologies.

A high-speed rotary rotor is a key component of a vacuum pump. Its blades move rapidly and between their respective stators. The gas molecules entering the inlet port are forced through the rotor, which acquires their preferred direction. The rotor can run at up to ninety thousand revs per minute. This type of speed helps the pump operate at a higher vacuum than other types of pumps.

The operating time of a vacuum pump depends on the operating pressure of the gas. Generally, this pump is used for ultrahigh vacuums. The differences between the different types of pumps are in manufacturing tolerances, sealing material, flow, and oil vapour admission. These factors affect the reliability of the vacuum pump. There are also differences in the operational time and service intervals. Some pumps are better suited for a particular application than others.

Vacuum pumps can be divided into two types: the claw and transfer pumps. The claw of a vacuum is a rotor that crosses the suction connection on each revolution. These pumps are more expensive than other vacuum pumps. However, the advantages of this type of pump are numerous. They can be used in a variety of industrial applications, including wood processing and packing. They can also be used in wastewater management. They make operations easier and more sanitary.

How It Is Used

A vacuum pump can be used in any industry where a high-pressure environment is required. Whether the process is rigid or delicate, it can be used in a variety of applications. Some of these applications include laser engraving. In fact, they are the perfect tool for any industry where precision and high-speed processes are crucial. A good vacuum pump can be a huge help in the printing industry. This machine can also hold up a printing plate during the laser etching process.

A mechanical vacuum pump is a great choice for a variety of vacuum applications. Various types of rotary vane and screw vacuum pumps can be used in freezing and process engineering. They use oil as a sealant and coolant, which makes them suitable for a variety of applications. The rotary vane pump is a great choice for many reasons. Its small size and versatility make it a great choice for the automotive industry.

The automotive electric vacuum pump market is being driven by fuel efficiency. This type of pump can be switched on and off according to demand, saving fuel and extending the life of the motor. Another benefit of the automotive electric vacuum pump is its ability to save space. This feature allows cars to have a compact design and save space. This is essential in the modern world because many of us have cars that don’t fit into our driveways. The best option is the one that offers the most room in the garage.